Precision sheet metal Work

High-tech sheet metal work

Qualified personnel

Our highly-specialised personnel can assist with co-design, product development and process industrialisation.

Complete supplies

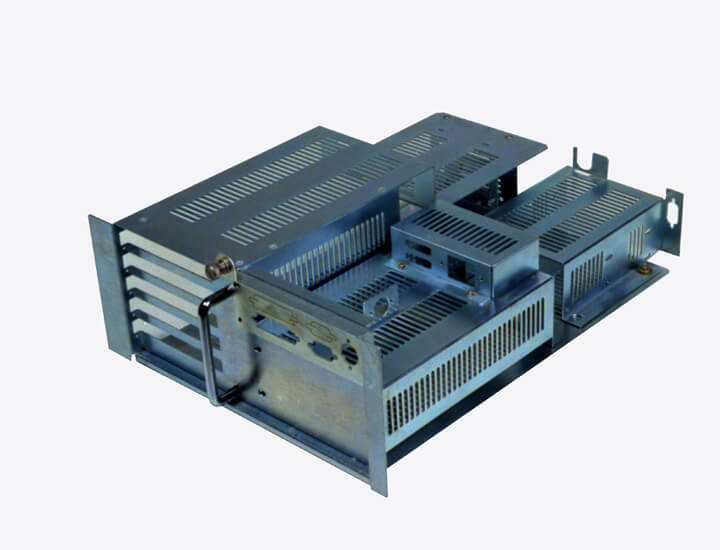

We manufacture samples, pre-series and serial sheet metal mechanical constructions, including painting, surface treatments and final assembly.

Customer service

Fast estimates, flexible production and priority to customer satisfaction.

Quality

The entire production process is subject to quality control procedures in accordance with ISO 9001.

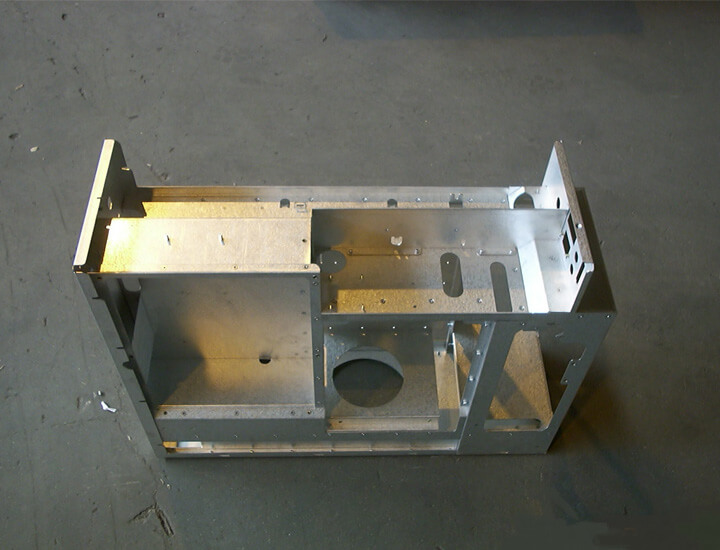

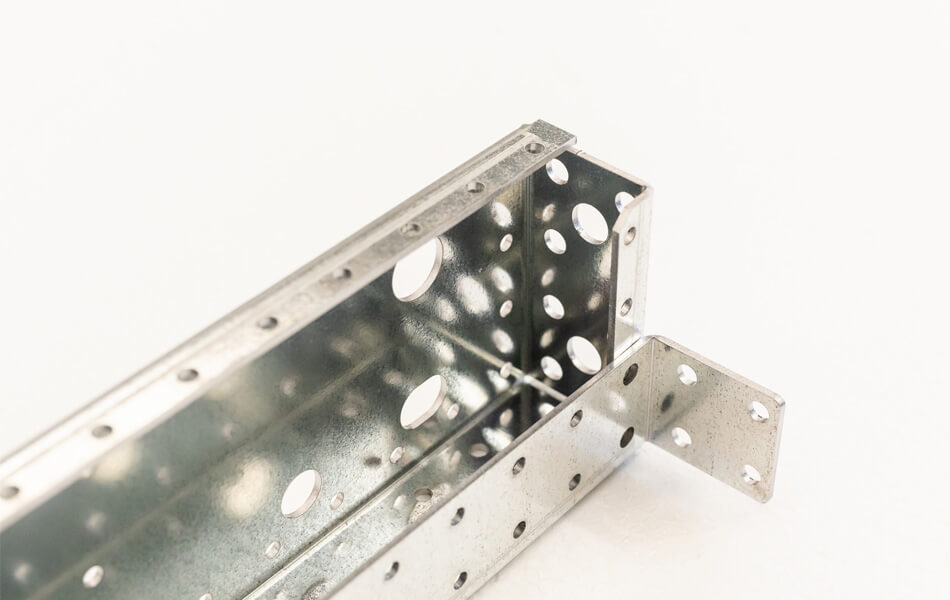

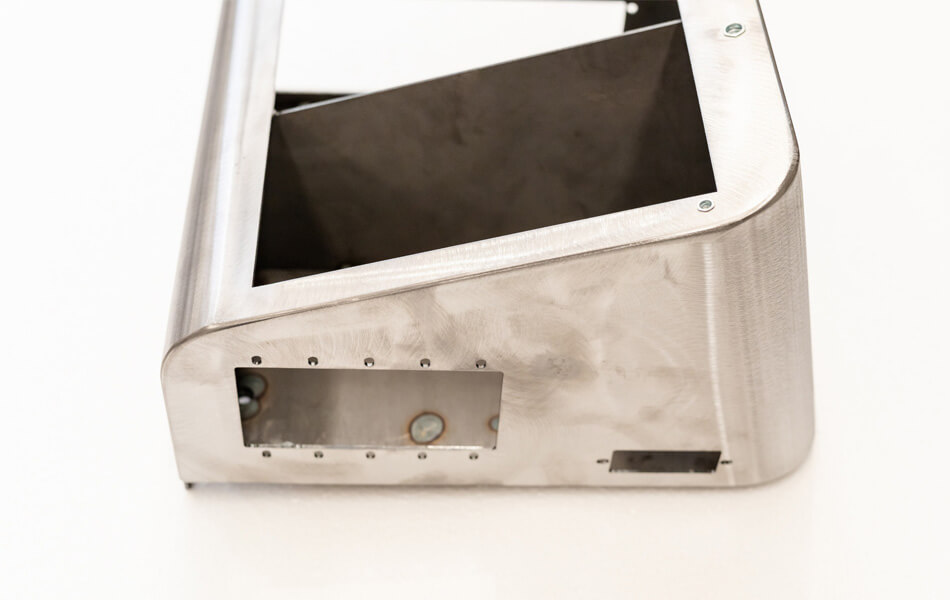

Supplies of semi-finished products built according to a drawing submitted

We manufacture a wide range of parts including cabinets, cabins and control or command panels, equipment sets, modular systems, furniture, cells, boxes, racks, baskets, crates, dashboards, lecterns, videos, covers, panels, frontages, floors, doors, partitions, mounts, shelving, ducts, button panels, boxes, structures and shelters, bodies and fairings, benches and tables (complete with cabinets, drawers, lecterns and guides), mounts and support structures. A complete response to market demand.

Materials

Thorough selection of raw materials and qualified commodity suppliers.

The main materials used are: steel, stainless steel, aluminium, various metals (including raw and pre-treated). All materials are certified.

Fields of application

Our consolidated experience and the flexibility acquired over the years allow us to provide tailored solutions for a wide range of sectors.

Electronics and Electrical

Air conditioning

Automotive

Telecommunications

Railway

Logistics and Automation

Discover our wide range of technological solutions, we can select them according to your needs

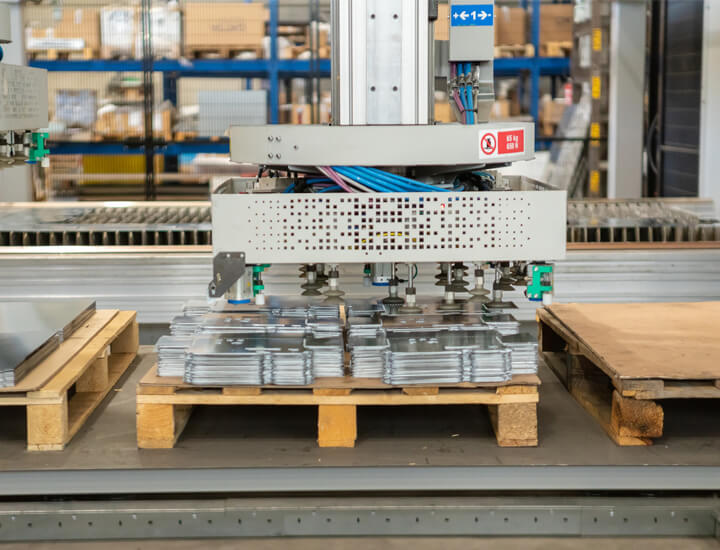

Automation and Customization

Discover our manufacturing processes

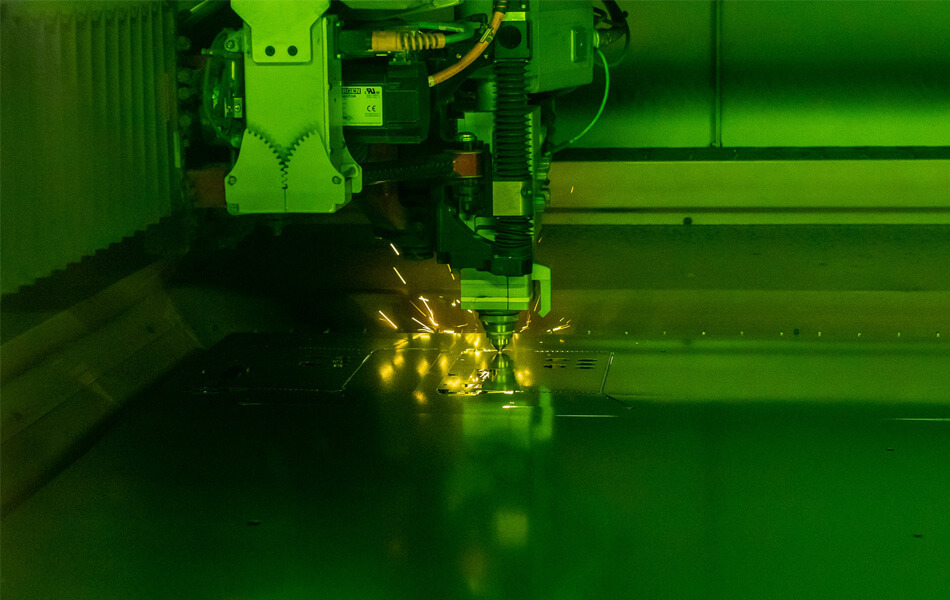

Cutting

Sheet metal cutting with fibre laser and punching technologies.

Bending

Sheet metal with bending machines of various tonnages and sizes.

Assembly and Welding

Assembly of semi-finished components according to the drawings submitted by the customer, with qualified TIG, MAG welding and final grinding.

Surface treatment

Painting, galvanising, cataphoresis, anodising and other special treatments.